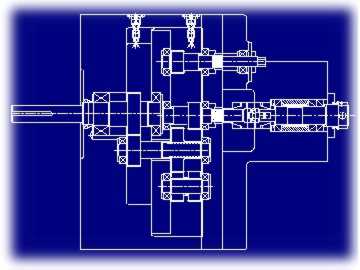

DIN Type Multi-Head

DIN-Type Multi-Head Features

Customer Friendly Pull-Out Spindle Cartridge DesignQuiet Running, Low Vibration Rotex Coupling for Backlash-Free Power Transmission to the SpindlesSpecial Air-Purged, Non-Contact Labyrinth Seal Design for Protection Against Coolant, Metal Chips, etc.Benefits of Permanently Kluber Grease. Lubricated Spindle Bearings Coupled with the Advantages of an Oil Lubricated Gear Chamber

Click for QuoteDIN-Type Multi-Head Construction

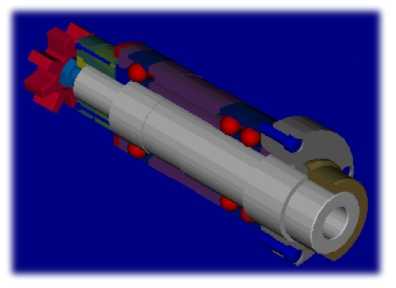

Pull-Out Din-Type Spindles (no fitting required during spindle replacement). Easy Access to Rotex Couplings. Permanently Kluber Grease Lubricated Class 7 Precision Spindle Bearings. Oil Lubricated Gear Chamber Using Spray Nozzles (optional). Oil Sump Can Be Carried in the Multi-Head or in a Separate Pump and Tank Assembly. Dry Chamber Isolates Kluber Grease Lubricated Spindles from Oil Lubricated Gear Chamber

Click for QuoteStandard Fixed Center Heads

Rapid Removal and Installation of Spindle Assemblies. Interchangeabliity of Like Spindle Assmeblies, No Fitting of Spacers. Easy Off-Line Rebuild of Spindle Assemblies Without Removal of Multi-Head. Permanently Kuber Grease Class 7 Precision Spindle Bearings

Click for QuoteClose Fixed Center Multiple Heads

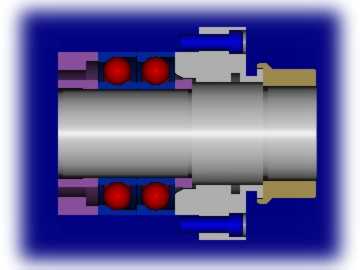

Special Air Purged Non-Contact Labyrinth Seal Design. Special Non-Contact Seal Design Means High Operating Speeds Without Excessive Heat Generation

Click for QuoteClose Fixed Center Specially Built Heads

Isolates Contamination to One Area of the Multi-Head. Separates Kluber Greases Lubricated Spindle Bearings from Oil Lubricated Gear Chamber. Houses the Rotex Spindle Drive Coupling

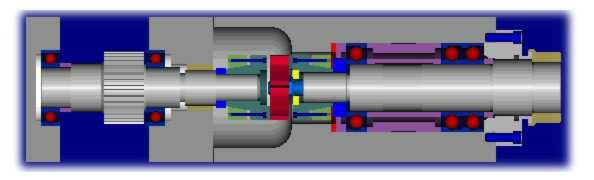

Click for QuoteFixed Center Oil Circulating Heads

Gears Machined Integral to the Shaft Providing Quiet, Low Vibration Operation. Special Non-Contact Seal Design for High Speed Operation or Lip Seal for Low Speeds. Oil Lubricated Gear Chamber Using Spray Nozzles (optional). Oil Sump Can Be Carried in the Multi-Head or in a Separate Pump and Tank Assembly

Click for Quote